Non-woven fabric machine manufacturer, Needle punching machine & molding machine

• Working Width : 2400~3000mm

• Needle Beam Stroke / Max stroke frequency - 30mm/1400 s/min

- 40mm/1200

- 60mm/1000

• Needle per Liner meter : 2000, 3000, 4000, 4500, 5000

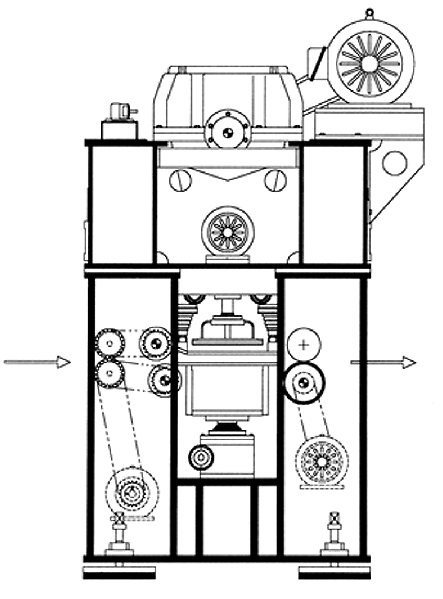

▶ Machine Structure

• The needle beam consists of two separate pieces, each piece being connected to one module box, so that it is easy to perform repair or maintenance.

• Power transmission parts, including bearings, within one module box, has their own individual lubricating oil pumps designed to feed oil at constant flow speed and pressure. when one of these pumps fails, the machine stops automatically.

• The machine is installed on the special vibroisolating rubber base to minimize the vibration of the machine. It is also easy to change the installation place of the machine.

▶ Needle Board

• The needle board is made of special aluminum alloy steel and polyurethane, so that it is not deformed and its needle holes do not become loose after use for a long time.

▶ Motors

• A variable speed AC-inverter (or DC motor) with 30HP(22kw) is used as main motor. It may vary depending on work load.

• A variable speed AC-inverter (or DC motor) with 1HP(0.75kw) is used as inlet and outlet motors.