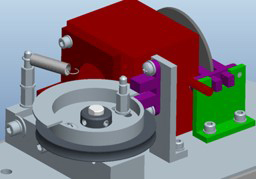

Imaging Scanning Monochromator

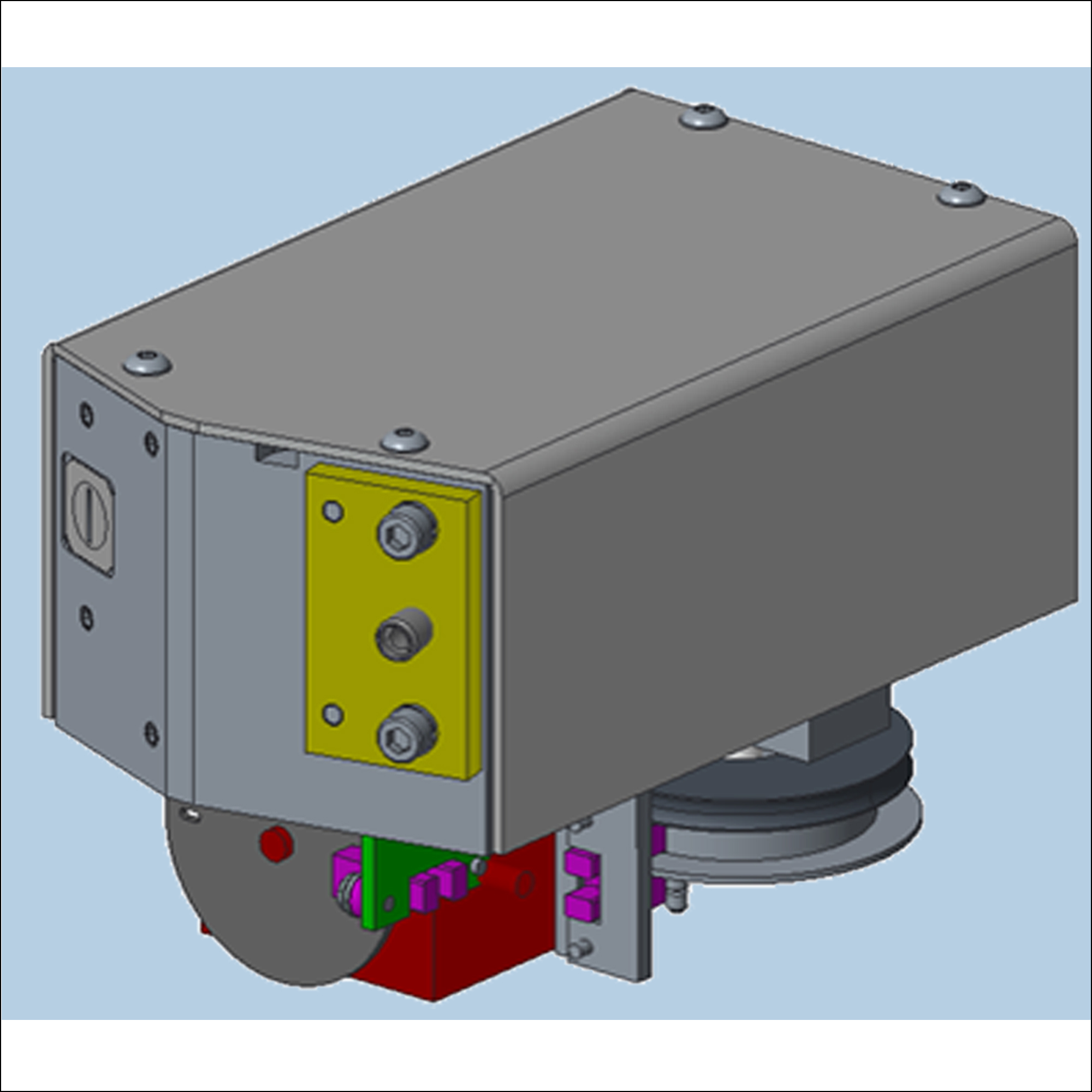

HORIBA Scientific OEM has developed a high-throughput imaging scanning monochromator based on an aberration-corrected concave holographic grating with low stray light and high efficiency. This proprietary layout with single optics design is ideal for imaging for low-light applications. It features a 3-position external filter wheel, TTL drive electronics, 4-phase stepper motor and associated worm/gear 90:1 ratio mechanism, encoded, aligned and focused at factory.

This instrument can be used as both a tunable excitation light source and a fluorescence emission scanning monochromator, thanks to high grating efficiency in both first and second orders of diffraction. It is also equipped with two opto-sensors and associated hardware for home calibration.

For OEM Industrial Applications

Absorbance, Fluorescence and Emission such as :

ㆍ Life Sciences (Plate Readers)

ㆍ Chemical Analysis

ㆍ High-performance Liquid Chromatography (HPLC)

ㆍ End-point Determination

ㆍ Color Measurement

ㆍ Environmental, Agricultural and Food

ㆍ Scanning monochromator with superb imaging

ㆍ Covering UV to NIR range

ㆍ High throughput and low stray light

ㆍ Fast, reliable and reproducible

ㆍ 4-phase stepper motor and associated worm/gear 90:1 ratio mechanism

ㆍ 3-position external filter wheel and TTL drive electronics

ㆍ Many grating choices

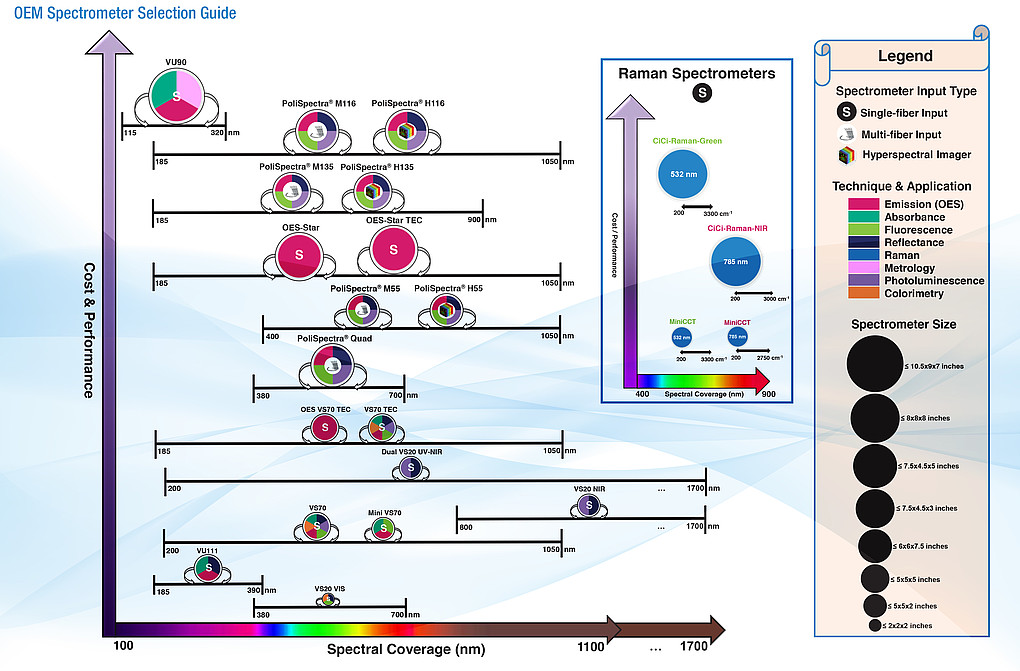

OEM Spectrometer Selection Guide

| General Monochromator Specifications* | |

|---|---|

|

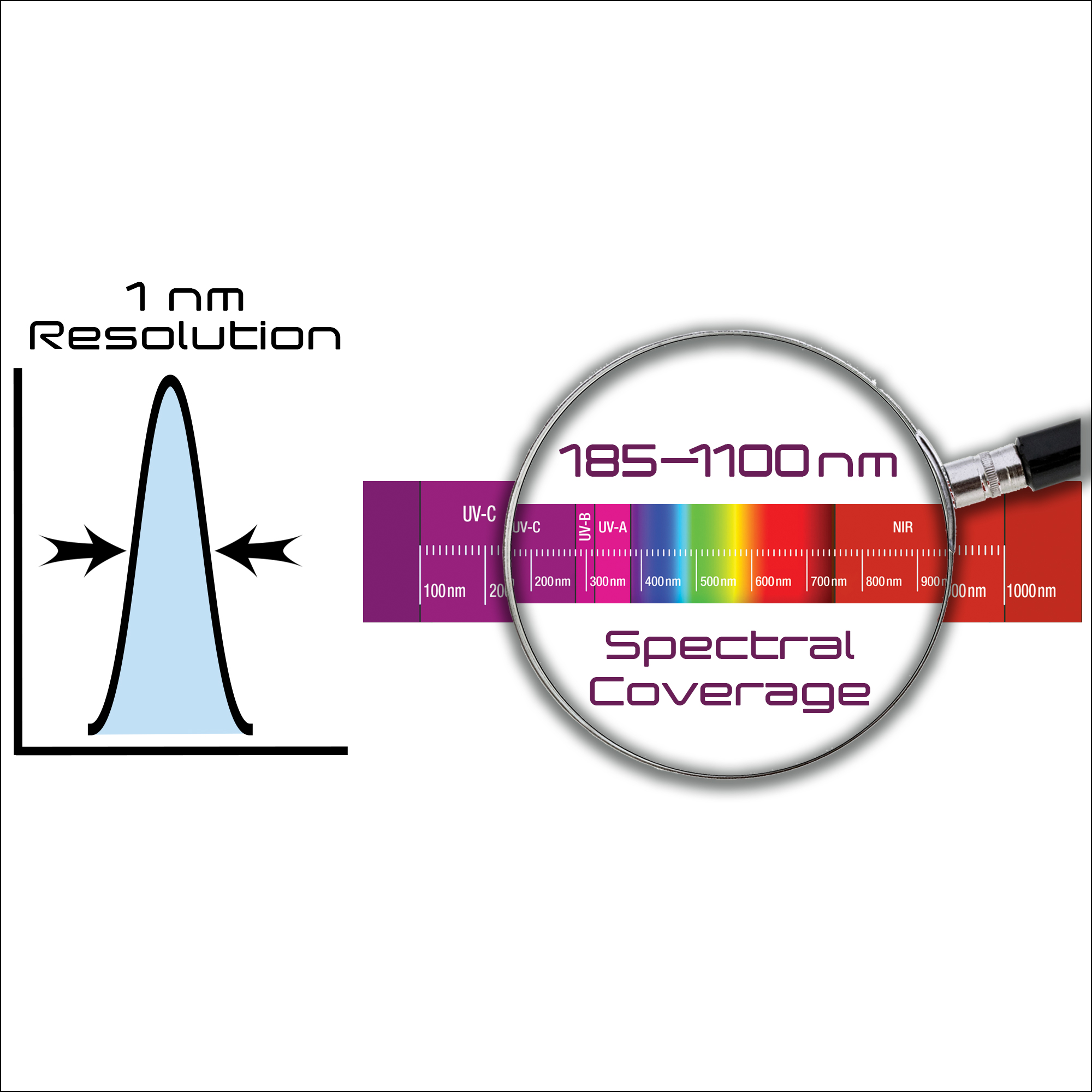

Spectral Coverage |

185 – 1,100 nm (Effective coverage depending on grating blaze selection) |

|

Spectrometer Input |

Free space; SMA; Customization on request |

|

Spectral Resolution |

<1 nm with 100 μm x 8 mm slit |

| Focal Length |

100 mm |

| Optical Dispersion |

7.8 nm/mm |

|

Stray Light |

< 0.1% (typical) |

|

Wavelength Accuracy |

± 1 nm with linear fitting |

| Step Repeatability | ± 0.1 nm (with 1,200 g/mm grating) |

|

F/# |

F/2.8 |

| Option: | OEM drive electronics with custom console app |

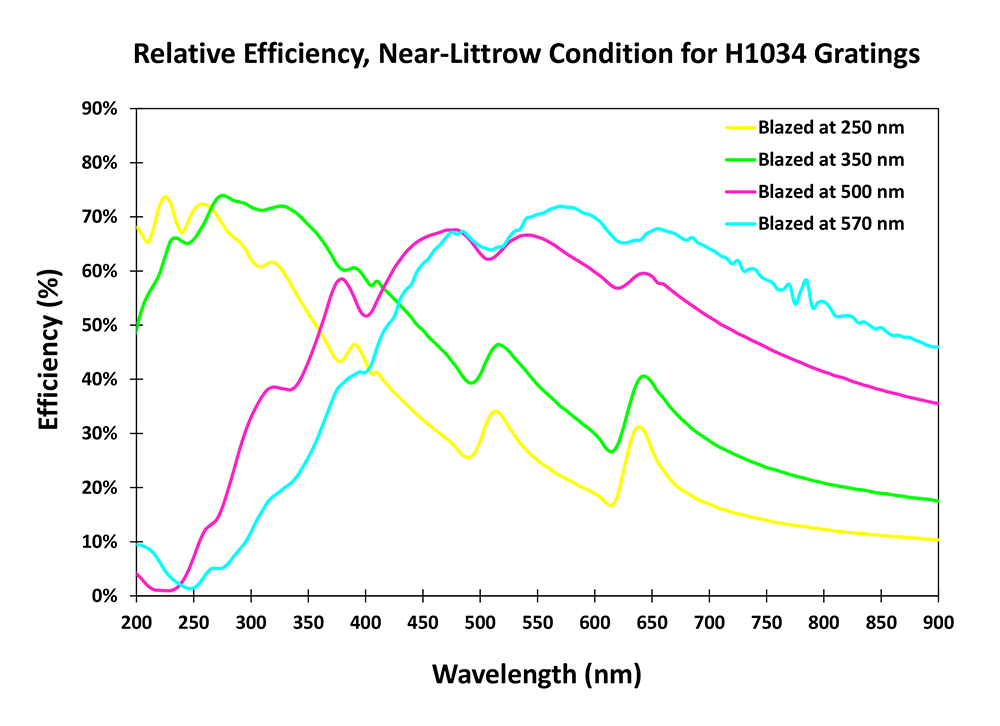

Grating Selection

H1034 monochromator can be built with several grating choices that all have the same parameters such as curvature, groove density, correction of the aberrations, angle of deviation, and more.

What differs among them is the blazed wavelength.

| Grating Type | Blaze Wavelength | ||||

|---|---|---|---|---|---|

| Aberration-corrected Concave Holographic Grating |

250 nm (covering 185-1,000 nm) |

350 nm (covering 185-1,000 nm) |

500 nm (covering 300-1,000 nm) |

570 nm (covering 350-1,000 nm) |

|

| Groove Density | 1,200 (gr/mm) | ||||

| F/# | F/2.8 | ||||

| Dimension | 38 mm x 38 mm and 42.4 x 42.4 (± 0.1) mm | ||||

| Input/output angle of deviation | 34.7° | ||||

| Input arm length | 105.19 mm | ||||

| Exit arm length | 100.46 mm | ||||

| Coating | Aluminum | ||||

| Grating efficiency | See the plots below | ||||

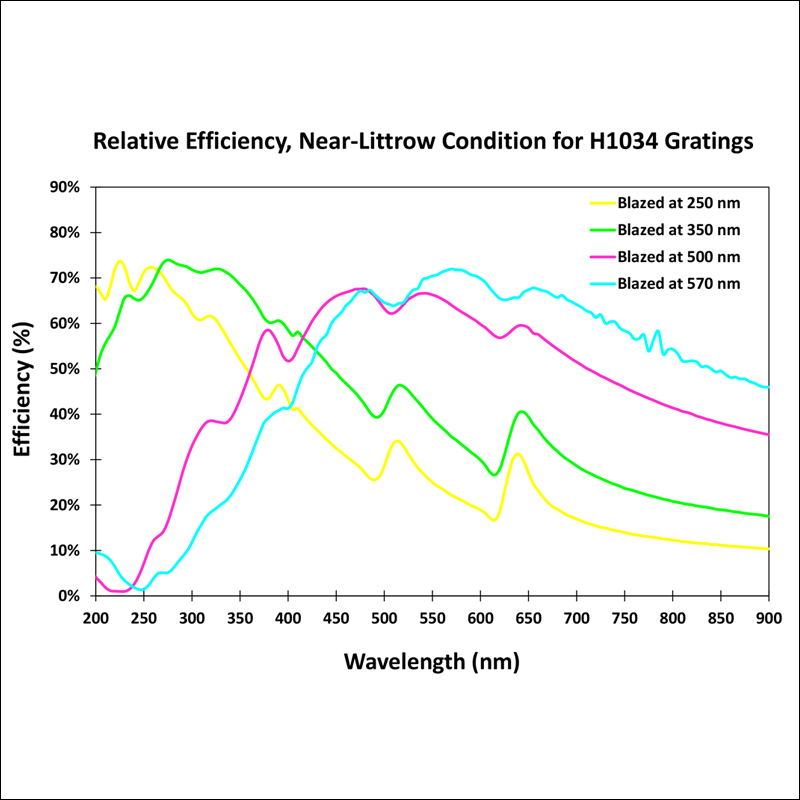

Grating Efficiency Curves

H1034 gratings can be used in first order for emission scanning and in second and first orders for excitation scanning.

Additional H1034 Monochromator Specifications

1-Motor Drive

H1034 monochromator features a 4-phase stepper motor and associated worm/gear 90:1 ratio mechanism, encoded, aligned and focused. Two opto-sensors and associated hardware for home calibration are included in this OEM configuration.

| Monochromator stepper motor scanning configuration | |

|---|---|

| Microstepping | 8 μ steps per step |

| Initial velocity or Minimum speed | 300 steps / sec |

| Maximum speed | 800 steps / sec |

| Ramp-up acceleration | 8,000 steps / sec2 |

| Ramp-down acceleration | 8,000 steps / sec2 |

| Threshold speed | 1,400 steps/sec |

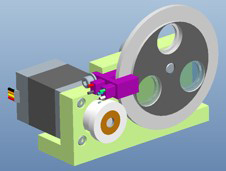

2- Filter Wheel (Optional)

Three-position compact filter wheel with NEMA 8 stepper motor and opto-sensor for homing that can be completely customized to customer’s requirements (number of filters, filter sizes, positions, etc).

| Filter wheel stepper motor scanning configuration | |

|---|---|

| Microstepping | 8 μ steps per step |

| Initial velocity or Minimum speed | 0 steps / sec |

| Maximum speed | 500 steps / sec |

| Ramp-up acceleration | 20,008 steps / sec2 |

| Ramp-down acceleration | 2,008 steps / sec2 |

| Threshold speed | 595 steps / sec |

3- Interchangeable Input and Output Slits (Optional)

H1034 monochromator is upgradable to have interchangeable input and output slits with various selections of slit width from 0.012 mm to 4.25 mm and 8 mm height.

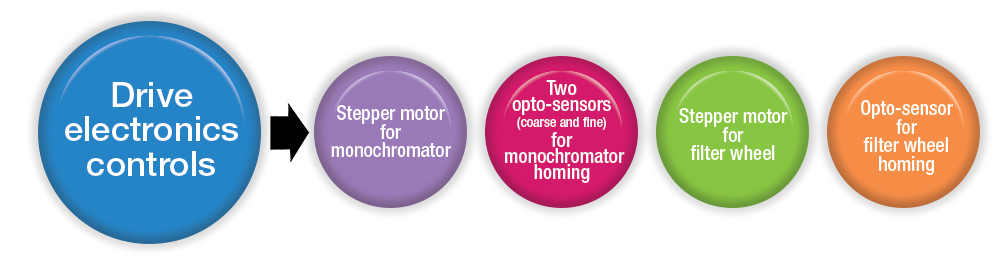

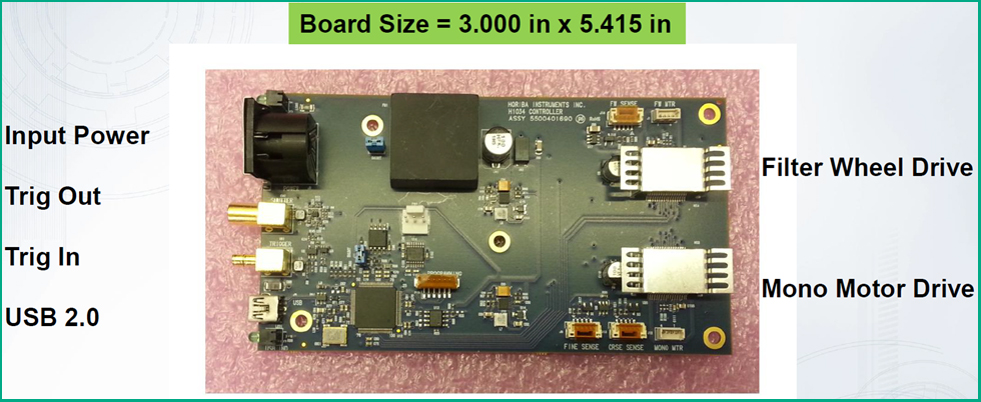

4- Drive Electronics for Monochromator and Filter Wheel

H1034 drive electronics with custom software is designed to control the monochromator components and its accessories.

Drive Electronics for H1034 monochromator system.

OEM Industrial grade.

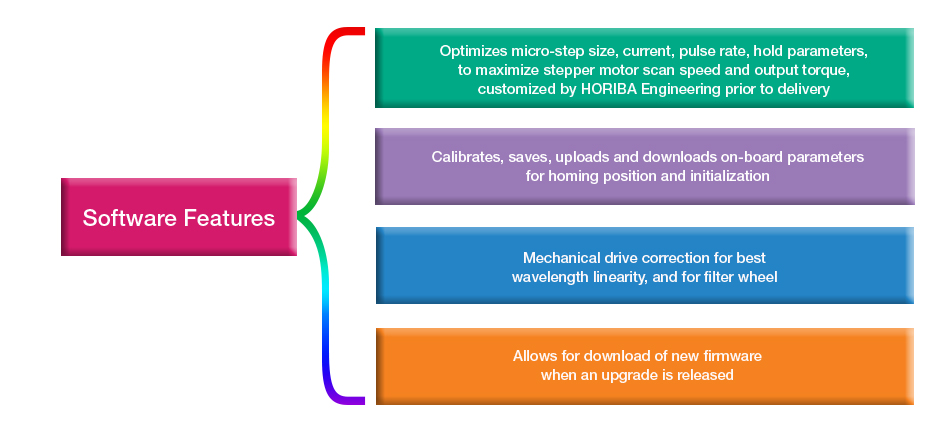

5- Console Application Software & DLL Features

OEM drive electronics has custom software for the H1034 monochromator and the optional shutter/order-sorting mechanism. It is delivered with a console app demo software for fast prototyping, debugging and testing with a super-user configuration tool for customization of the operating parameters, a DLL driver and associated documentation for custom programming (e.g., C#) and integration within the customer’s top-level software.

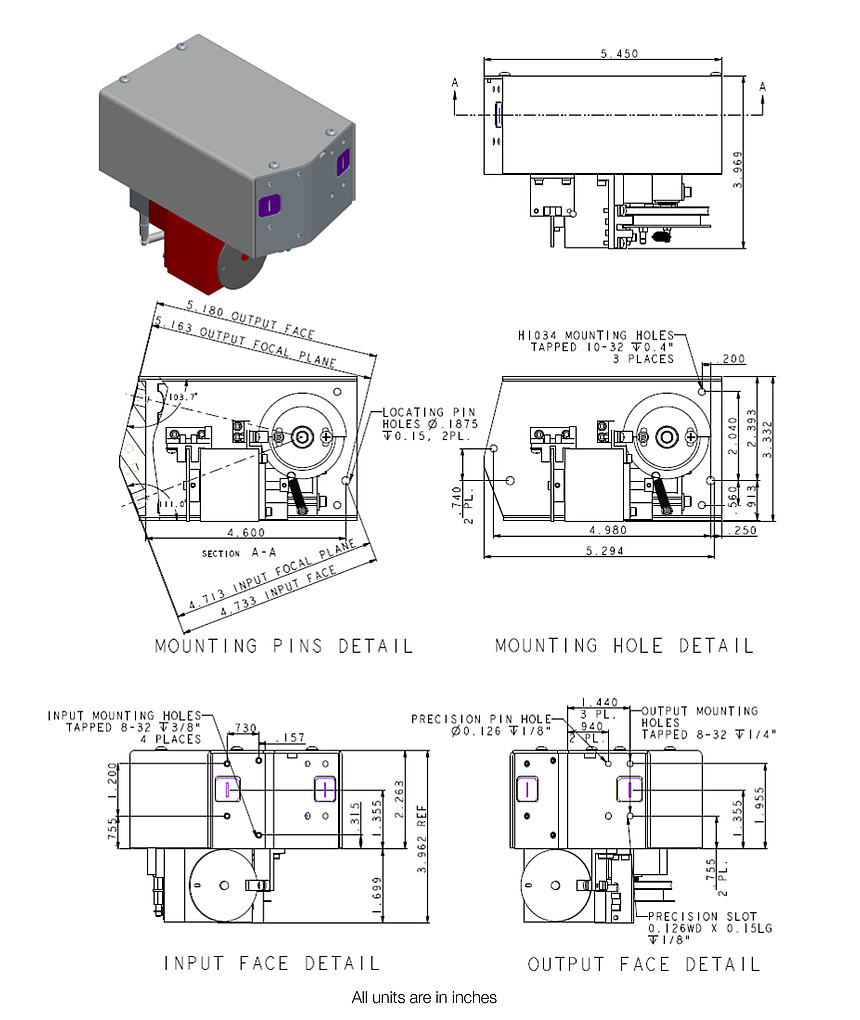

Mechanical Drawings