OEM gratings design and production capabilities

HORIBA Scientific produces a wide range of holographic master gratings from which high precision replicas are manufactured.

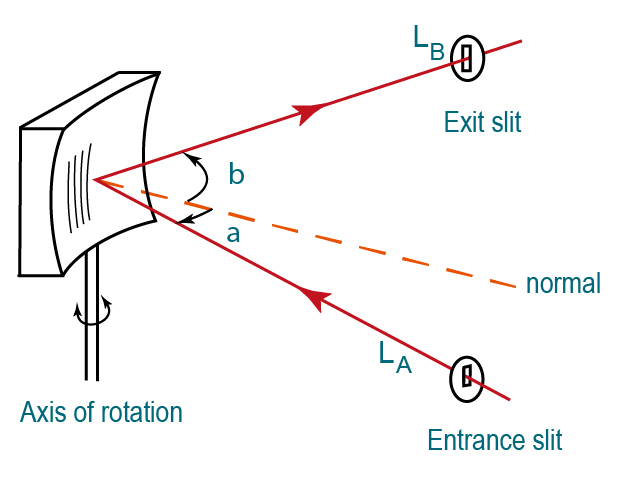

Using Type IV aberration-corrected monochromator gratings, a single concave grating disperses, collimates, and refocuses the light from the entrance slit onto the exit slit. Wavelength scanning is obtained through a simple rotation of the grating.

The groove spacing of these gratings is computer-optimized to produce high quality images with a minimum of astigmatism and coma, even at large numerical apertures. Compared with Czerny-Turner monochromators (equipped with one plane grating, one collimating mirror and one focusing mirror), Type IV aberration-corrected monochromator gratings provide much better light collection efficiency and signal-to-noise ratio.

ㆍ Replica gratings from aberration corrected master gratings

ㆍ Holographic Master can be blazed by Ion-beam etching method for higher efficiency

ㆍ Ideal for robust, compact and low stray light monochromators

ㆍ Several references available some (not all are listed in the catalogue)

ㆍ Large range of dispersion available

ㆍ Multiple spectral range from UV to IR

ㆍ Coating: Al or gold.

Fig. 1: Monochromator concave grating

LA: distance between the grating and the entrance slit

LB: distance between the grating and the exit slit

D: deviation angle

F/#: optical aperture

Fig. 2: Imaging Scanning Monochromator

|

Product Management and Quality

|

Customer Oriented and Confidentiality

|

ㆍ Spectral ranges: from 190 to 10,000 nm

ㆍ Large range of groove densities: from 100 to 2000 gr/mm

ㆍ Diffraction efficiency optimized for UV, or Vis, or NIR

ㆍ Radius of curvature : from 100 to 1232 mm

ㆍ Dimensions : from 25 x 25 mm

ㆍ For customers in need of larger dimensions, HJY can record a custom-made holographic grating master specifically for replication.

Fig. 3: Typical efficiency curve* for 532 00, 1200 l/mm, 190-1050 nm

*This efficiency curve is absolute theoretical efficiency, calculated using rigorous electromagnetic theory, taking into account the true groove profiles of manufactured gratings measured with an atomic force microscope (AFM).